Simplifying commissioning.

Trusting expert knowledge.

Rediscovering fieldbus.

Fieldbus Diagnostic Handheld FDH-1

Fieldbus Made Easy – Features of FDH-1

Embedded Expert System

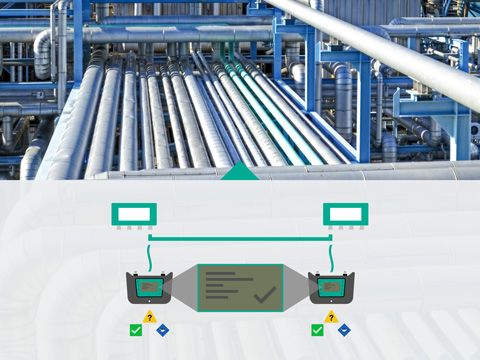

Quality Assurance at the Touch of a Button

Handheld Convenience

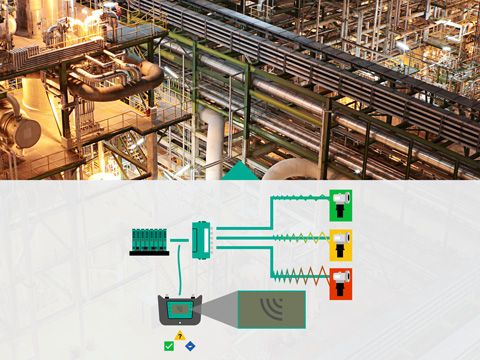

Use Cases of FDH-1

White Paper Explains Efficient Commissioning with Fieldbus

Today’s fieldbus installations in process automation, FOUNDATION Fieldbus H1 and PROFIBUS PA, can be greatly improved with a fully automated fieldbus test methodology. The work procedure described in the white paper achieves better installation quality and eliminates the time crunch during commissioning. See a preview of the technical white paper "Fieldbus Testing with Online Physical Layer Diagnostics".

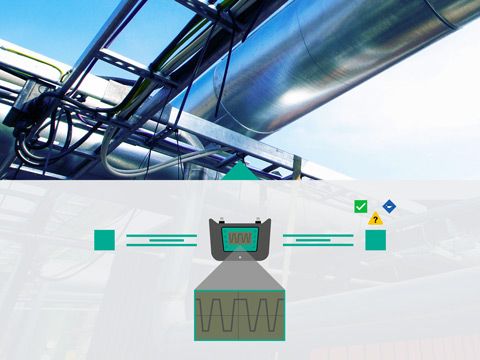

Quick Check Simply Explained

How do I check the fieldbus installation using the FDH-1 quick check mode?

In this How To video, Product Marketing Manager Andreas Hennecke answers the question step by step.

You’ll be surprised by the handheld’s easy handling! …

お問い合わせ

Do you have any question on the Fieldbus Diagnostic Handheld?

We're here to help! Simply send us an email or make an appointment to get more information on the FDH-1.

Downloads

Downloads

More Information

More Information

- Fieldbus Diagnostic Handheld FDH-1 See all technical information about the FDH-1.

- 5 Reasons for the Fieldbus Diagnostic Handheld FDH-1 Read five reasons why the FDH-1 simplifies your fieldbus installation.

+81 45 6249077

+81 45 6249077