1. Risk Analysis: Establish Required Risk Reduction

First, all existing risks are identified during the risk analysis. It must then be established whether reduction is required for each identified risk. If so, the required risk reduction must be quantified using risk analysis methods that deliver results in the form of a SIL requirement.

A low SIL requirement (SIL 1) means that only a comparably low risk reduction is necessary, whereas a higher SIL (for example SIL 3) requires a greater degree of risk reduction.

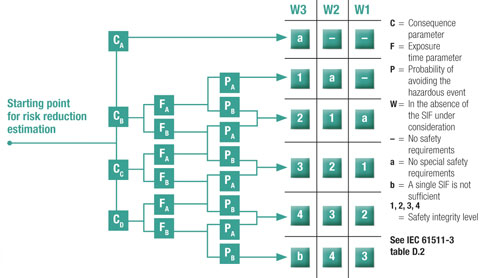

Various procedures are available to identify risks and quantify any necessary risk reduction, usually with software support. The process for identifying risks is frequently performed in conjunction with the "Hazard and Operability Study" (or HAZOP for short). The usual methods used to quantify the necessary risk reduction (SIL evaluation) include a risk graph, LOPA ("Layer of Protection Analysis") and risk matrix.

Risk graph

+81 45 6249077

+81 45 6249077